Description

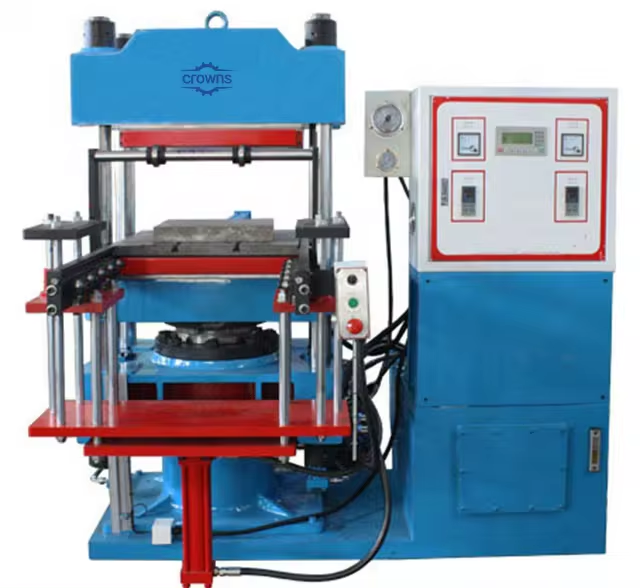

The other part is automatic lifting platform which it’s workflow

– Remove the finished mould template from the open work area,

-Then drop to the height of the work;

-The insulation board will be taken out by manipulator or manual work, process paving work and feeding the mould template into the pressure machine;

– Take out the next template until the three panels are finished.

2.Main technical parameters and description of equipment

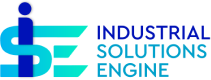

2.1 Model: JXLC-3+3-12500*1450

2.2 Max processing dimension:12000mm*1200mm.(3~14m is optional)

2.3 Number of Pallets:6 pieces

2.4 Processing thickness;50~200mm

2.5 Working pressure:16MP

2.6 Clamping force of mold: 300T

2.7 Hydro-cylinder:125mm*16 units

2.8 Clamping speed:1m/minute

2.9 Hydraulic power:15KW

2.10 Lifting of platform lifting:Hydraulic lifting or wire rod lifting can be selected according to the user’s site and the situation with auxiliary equipment

2.11Lifting speed:1.5m/minute

2.12 Template translation:The template translation is controlled by the stepping motor with a speed of 12m / min.

2.13 Synchronization system: The traveling speed of the platform is consistent during the control of the synchronous system.

Reviews

There are no reviews yet.