Description

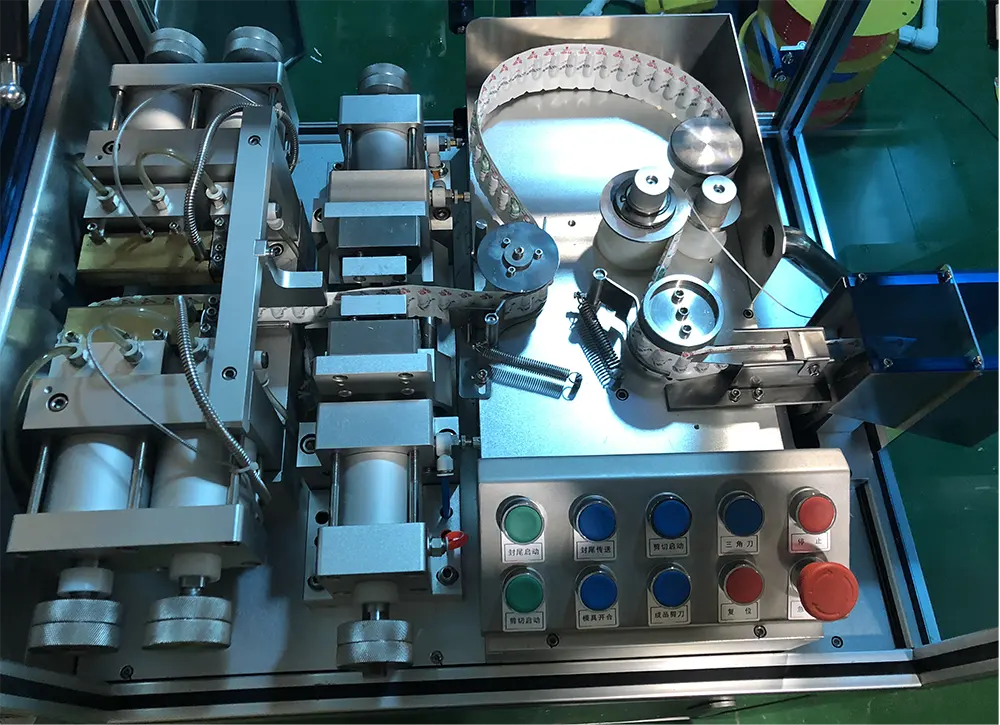

The SJ-3L automatic suppository filling production line has a stable and efficient manufacturing process, filling, freezing, sealing and other production processes to complete the whole process, and the production capacity is 5,000-6,000 grains/hour.

Process flow

It will be rolled into the forming area by the clamping mechanism. The mold will be heated by the preheating mold, the mold, themold, the blow mold and the bubble forming.

heating insulation system, the top is equipped with a uniform mixing machine by high precision in VAT filling pump into the filling head, an item through the other end of the cycle to rest after filling material barrel filling again next time.

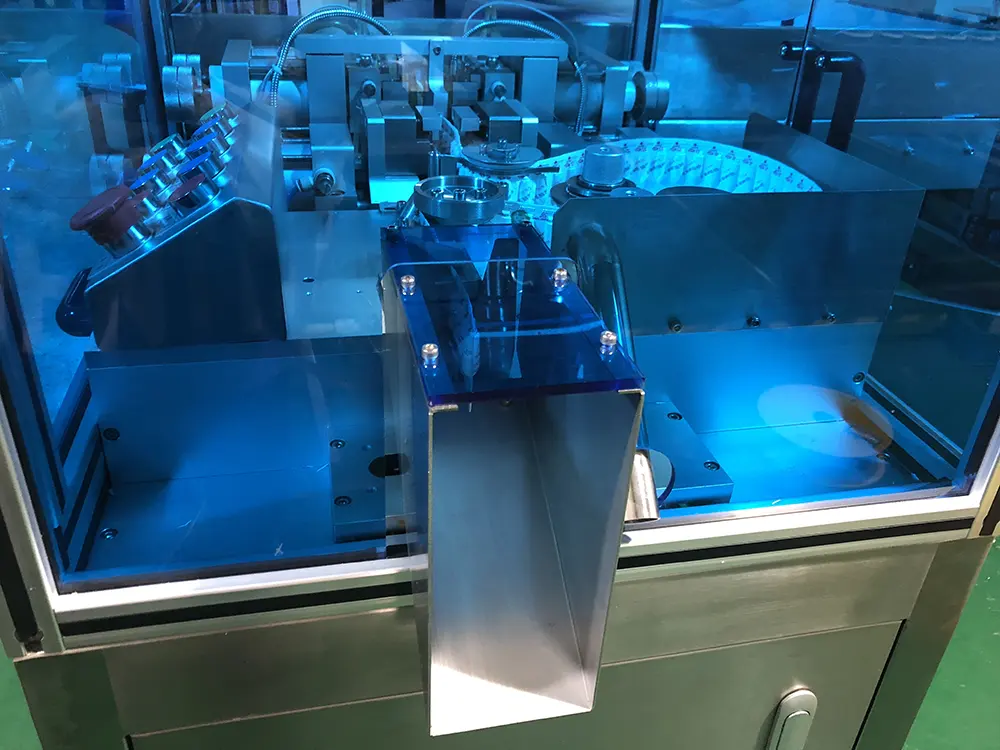

Cooling design

The suppository of the whole drainage is entered into the cooling box, and the cooling box is equipped with a cold water unit.

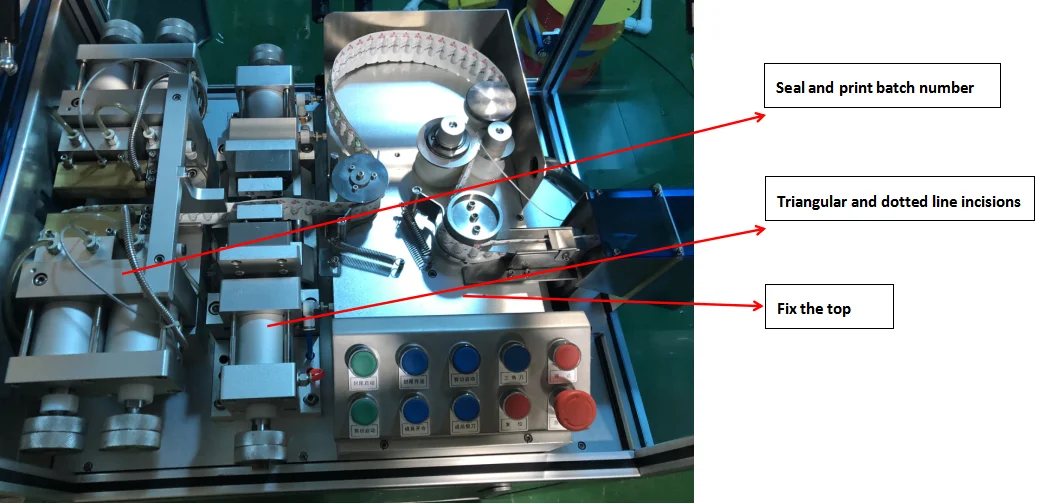

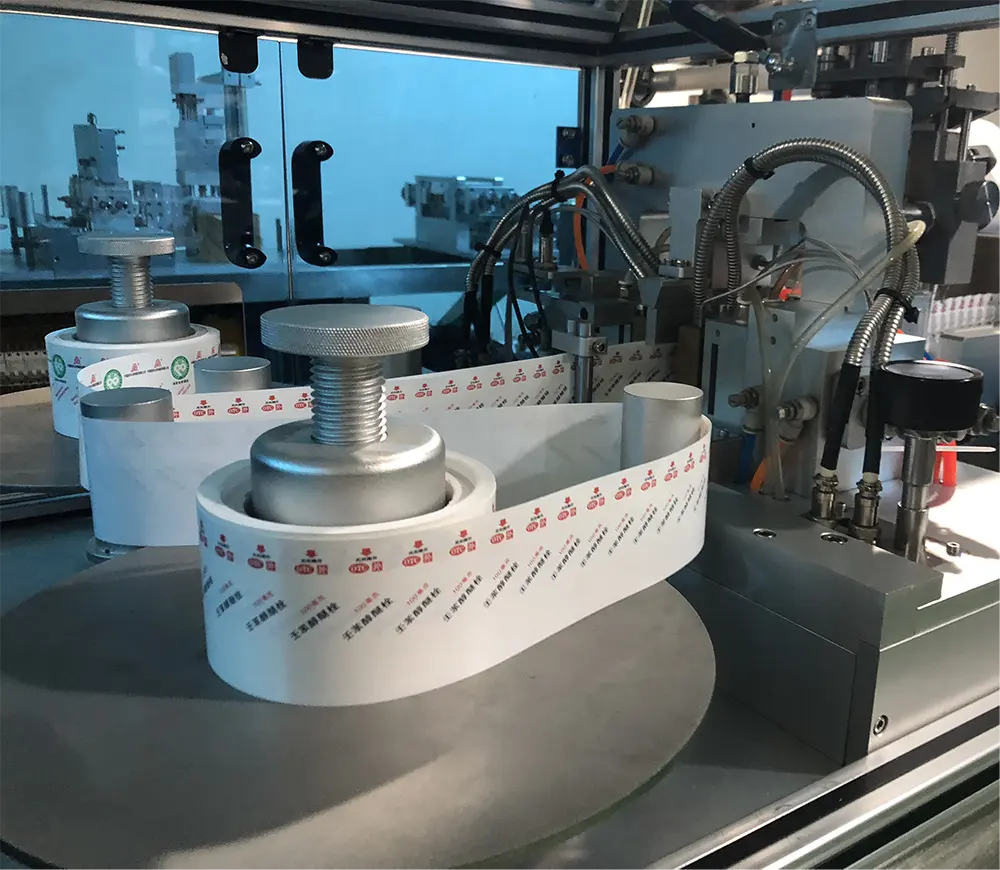

Shearing

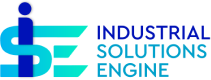

After being cooled, the solid suppository enters the sealing zone: preheating mold (preheating), sealing mould (seal), marking mould (batch number), The triangle knife will be cutting suppository top edge (cutting edge),hob (top), counting shear.

Reviews

There are no reviews yet.