Description

China Made Extruder Machine For Making HDPE PVC Plastic Waterproof Dimpled Drainage Membrane Sheet Board Panel Production Line Manufacturing Plant Equipment

|

Raw Material

|

HDPE/PP /PVC

|

|

Final product

|

Dimpled Drainage sheet /board

|

|

Usage

|

waterproof

|

|

Width

|

Customized

|

Product Application

PVC /HDPE Drainage Sheet/Board Production Line/Machine/Plant/Equipment

PVC/HDPE Drainage Plate Extrusion/Extruder/Extruding Line

PVC/HDPE Drainage Sheet Processing/Manufacturing

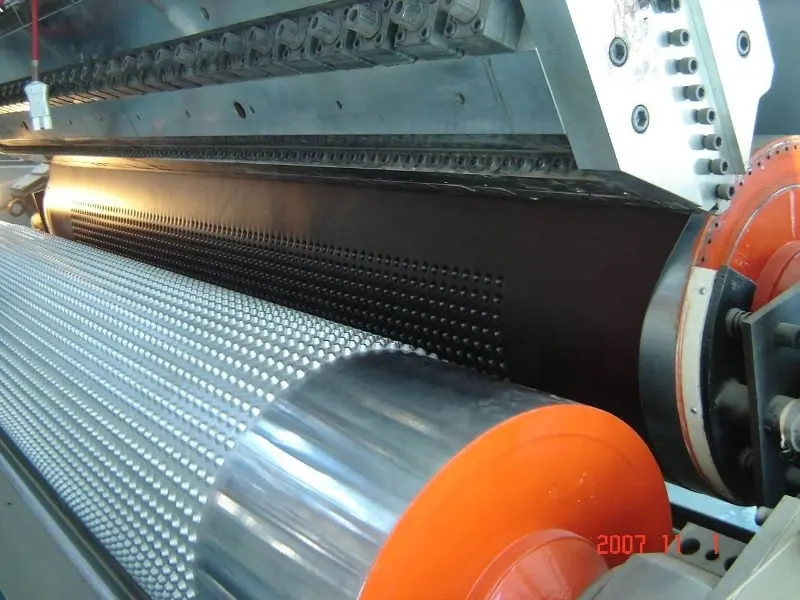

HDPE drainage sheet extrusion line is very fashional product. On the base of our conventional sheet machine, we refreshed the rollers on the calendar, and got further development in this industry.

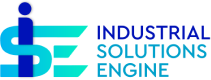

The final HDPE sheet is a dimpled plastic sheet that can be used in various waterproofing applications. The dimpled nubs create a vapour and thermal insulation barrier for both internal walls and walls that are adjacent to waterproofing membranes, while also protecting the waterproofing membrane from the backfill in underground structures.

The Drainage Sheets offer protection against any dampness in ground slabs and also create a cavity control layer, while The integrated non-woven geotextile covering the nubs prevents soil particles blocking the drainage sheet, creates an air gap for reliable ventilation and allows inflow and transport of water from surrounding soil.

Applications of HDPE drainage sheet:

Retaining Walls

Basement Walls

Tunnels and landfills

Reduction in hydrostatic pressure behind retaining structure

Additional protection to waterproofing membranes

After Sale Service

1.Warranty period is 12 months from the date of finishing installation.

2.The seller should supply the parts which is damaged non-contrived and is included in the standard configuration of this machine without any charges. The seller pay for freight in China, and the buyer should pay the freight out of China.

3.The seller will send technician to buyer to maintain the machine within the warranty period of this machine.

4.The seller should supply spare parts and service of maintenance to buyer out of warranty period, but the buyer should pay for the cost of parts and freight out of China and pay lodging and dinner, medical treatment, etc.

5.The buyer should get all conditions (raw material, water, power, compress air and tools) for installation and commissioning well before seller’s technician arrives at buyer’s factory.

6.The seller should send technician to buyer’s company make installation and commissioning of this machine. The buyer should pay for the charges of lodging, meal, round ticket and inland traffic to seller’s technician. USD 100.00 each day will be paid to each technician.

7.The seller supply training service for buyer without any charges before shipment, and can train buyer’s technicians continuously when seller’s technicians install and adjust the machine.

8.The seller should supply installation instruction and manual in English.

Reviews

There are no reviews yet.