Description

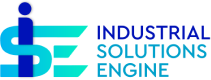

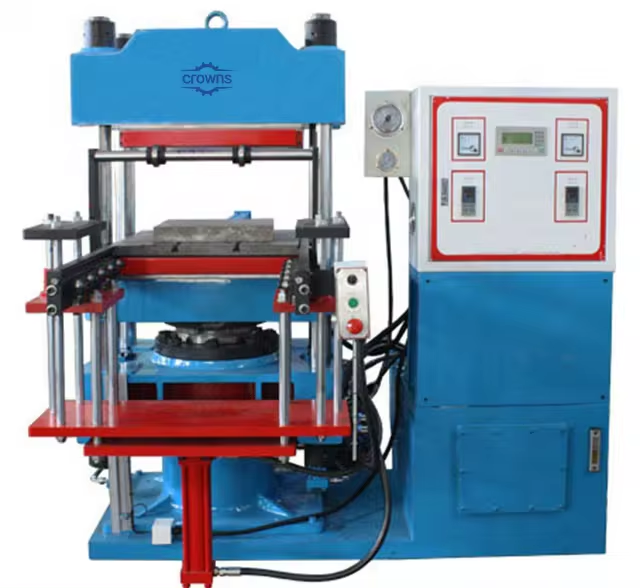

Rubber Hydraulic Plate Curing Press Machine is the machine used to make rubber products . The machine can be used to make rubber molded products as well as non-molded products. This machine can also be used as a hydraulic cold press machine.

As a column structure and downward pressing type, the heating plate opens by the self-weight of the heating plate, platform and plunger. The rising of the plunger makes the heating plate close while the hydraulic oil provides the pressure.

The base is combined together with the cylinder and base frame, which is made of ductile iron to increase the cylinder intensity and a brad ability. The cylinder is fitted with the sealing washer made of the oil-resisting rubber for the sealing purpose.

By moving the operational handle of the control valve to the two different positions, the heating plate can open and close.

Below is common used rubber press machine models. If you need other size or pressure, please just feel free to contact us.

|

Item

|

XLB-D(Y)1000*1000*1

|

XLB-D(Y)1200*1200*1

|

XLB-D(Y)1500*1500*1

|

|

Nominal molding power

|

1.60-2.00MN

|

3.15MN

|

4.00-5.00MN

|

|

Working layer number

|

1

|

1

|

1

|

|

Piston stroke

|

250-500mm

|

250-500mm

|

250-500mm

|

|

Main motor power

|

3.0kW

|

3.0kW

|

3.0kW

|

|

Plate clearance

|

125-500mm

|

125-500mm

|

125-500mm

|

|

Heating method

|

Steam,ecectricity

|

Steam,ecectricity

|

Steam,ecectricity

|

|

Configuration

|

Frame

|

Frame

|

Frame

|

|

Electric pipr heating power

|

12kW

|

15.6kW

|

27kw

|

|

Model

|

XLB350x350x2

|

XLB400X400X2

|

XLB500x500x2

|

XLB600x600x2/4

|

XLB750x850x2

|

|

Nominal mold clamping force(MN)

|

0.25

|

0.5

|

0.8

|

1.0

|

1.6

|

|

Space between hot plate(mm)

|

125

|

125

|

125

|

125

|

125

|

|

Working layer of hot plate

|

2

|

2

|

2

|

2/4

|

2

|

|

Unit area pressure of hot plate(Mpa)

|

2.04

|

3.13

|

2.52

|

2.78

|

2.51

|

|

Plunger stroke(mm)

|

250

|

250

|

250

|

250/500

|

250

|

|

Heating mode

|

electric/steam

|

electric/steam

|

electric/steam

|

electric/steam

|

electric/steam

|

|

Main motor power(kw)

|

2.2 |

2.2 |

2.2 |

2.2 |

3 |

|

Overall dimensions(mm)

|

1450x400x1350

|

1600x400x1440

|

1450x690x1818

|

1880x780x1660

|

2100x1010x1900

|

|

Machine weight(kg)

|

1200

|

1500

|

1700

|

2500/3100

|

3560/4300

|

|

Structural form

|

post type

|

post type

|

post type

|

post type

|

post/box type

|

FAQ’s

Q1: Where is your factory located?

A1: Qingdao crowns machinery co.,ltd is located at Huangdao district ,Qingdao city, China

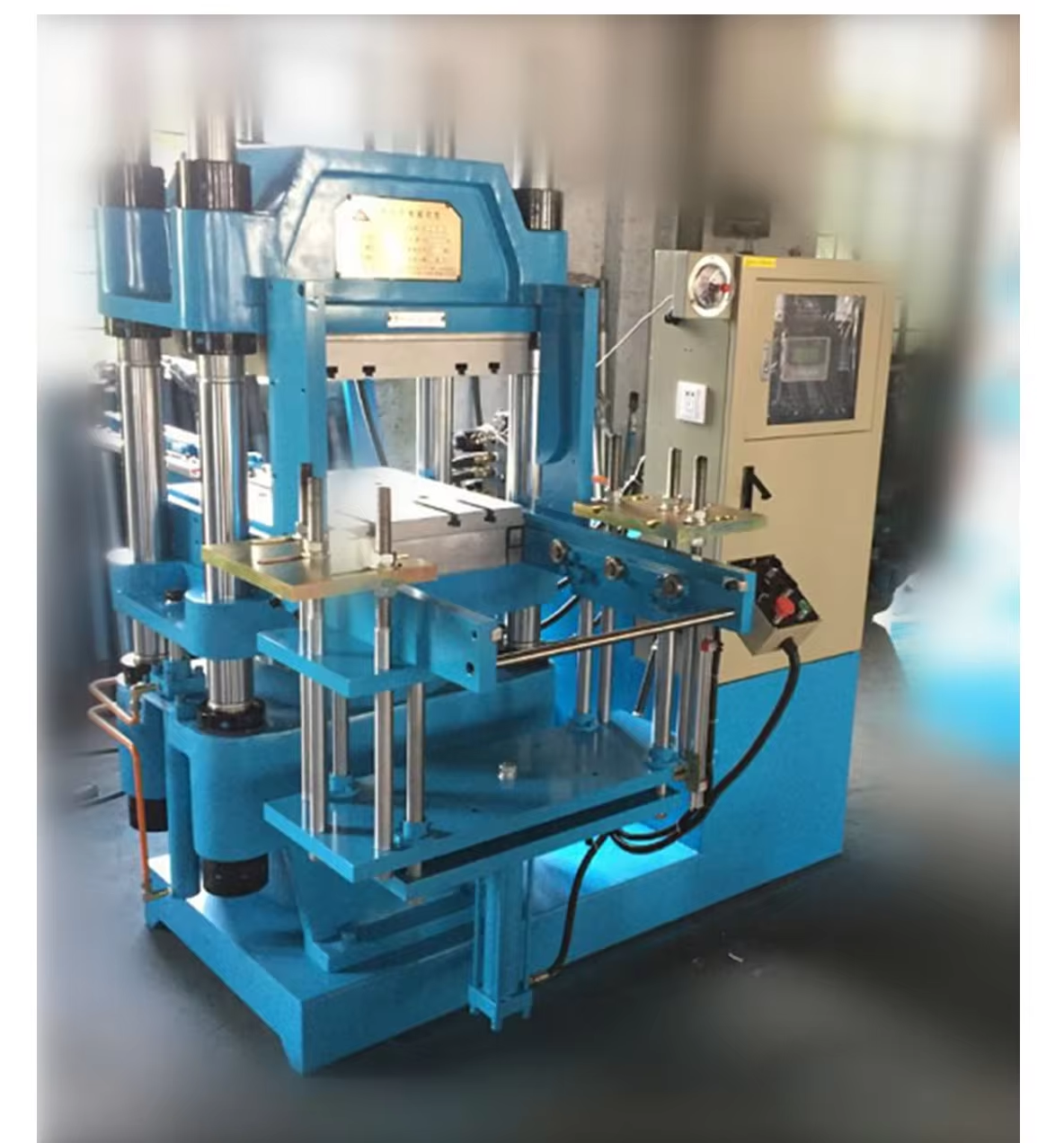

Q2: Are you an integrated supplier for rubber&plastic machine ?

A2: Yes, we can provide the complete solution line to customer according to customer’s requirement.

Q3: How about the quality control in your factory?

A3: Qingdao crowns has the SOP (Standard Operation Procedure) and all the production step must follow up this SOP. Every machine needs at least automatic running over 72 hours and must be inspected carefully before shipment.

Q4: Will you offer the pre-sales service?

A4: Yes, we have an experienced pre-sales team to support customers not only including machine, technology also water

.electrical,machine layout in factory, etc.

Q5: What about the after-service? Will you send your engineer to my country to help commission and install the machine?

A5: Surely, we have many experience technical engineers for oversea service, they would help you install machine and support training to workers also.

Q6: What is the delivery time of the machine?

A6: Actually, the delivery time of the machines is depended on the machine options. Normally, the delivery time of standard machine could be within 10-30 days

Q7 : What is the warranty of the machine ?

A7: The whole machine’s warranty period is 12 months and key parts will be depended.

Q8 : Do you provide any spare parts with machine?

A8: Yes, CROWNS will provide one set standard spare parts to customer according to different machines

Reviews

There are no reviews yet.