Description

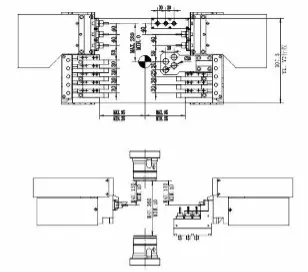

1. The maximum machining diameter of the bar stock reaches Ø36mm.

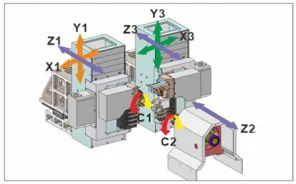

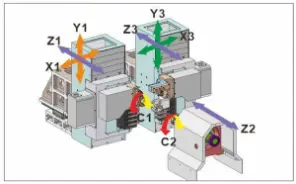

2. The standard configuration includes 7 feed shafts and 2 opposite spindles, which support automatic butt joint of workpieces.

3. Two sets of independent tooling mechanisms allow simultaneous multi-tool machining for balanced operation of turning and milling.

4. Synchronized motorized spindle makes high torque output come true.

5. The operating system is mounted on a 180-degree rotating arm, and the door may be opened in front and back of the machine tool for convenient operation and manipulation.

6. It is provided with open design and excellent chip removal

| Standard Accessories | |

| Synchronous motorized spindle | Signal lamp (3 colors) |

| Tools and toolbox | Circular hole tool holder |

| Centralized lubricating device | Receiver |

| Handwheel simulation function | Cs axis functions |

| A set of operation instruction | Lathe tool holder |

| Motorized spindle oil cooler |

LED lighting device |

| Optional Accessories | |

| Special fixture | Door switch detection |

| Tool blowing | Power tool device |

| Center water outlet | Electric cabinet air conditioner |

| Non-standard automation | Clamping detection |

| Automatic chip remover | Tool rear water outlet |

| High pressure cutting oil cooling | Oil mist collecting device |

Reviews

There are no reviews yet.